Welcome to Guangzhou Shipyard International Co., Ltd.!

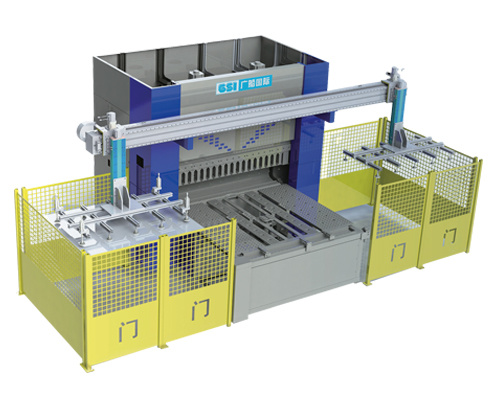

MK SERIES CNC HYDRAULIC BRAKE PLATE SHEARS

Category:

SHEET METAL EQUIPMENT

SHEARING MACHINE

Product details

The frame is designed by finite element analysis, and the steel plate is welded as a whole, which has good rigidity and stability.

The frame is integrally processed by large CNC boring and milling machine to ensure the shearing accuracy and quality.

The machine adopts a four-cylinder structure, and the knife beam is suspended and supported by the cylinder, without rigid connection, reducing the failure rate.

The tool rest is supported by three rolling guide wheels to eliminate the shearing gap and improve the shearing accuracy.

Four-blade scissors are used to greatly improve the service life of scissors.

The blade gap is adjusted by hand wheel and displayed by dial, which is simple, intuitive and accurate.

The shearing stroke can be adjusted steplessly to improve the shearing efficiency.

The series cylinder synchronous system is adopted, and the return stroke of the energy storage cylinder is stable and reliable.

The special CNC system for GSI plate shearing machine is equipped as standard, with high precision and easy to use.

The rear stopper adopts ball screw, linear guide rail structure and servo motor drive, with accurate and reliable positioning.

The front holding rod is equipped with a front positioning scale and a mechanical stop for positioning, which can meet different operating requirements of users.

Optional pneumatic rear support and front automatic feeding table.

key word:

Elevator electromechanical equipment

CNC bending machine

Welcome to leave a message for consultation